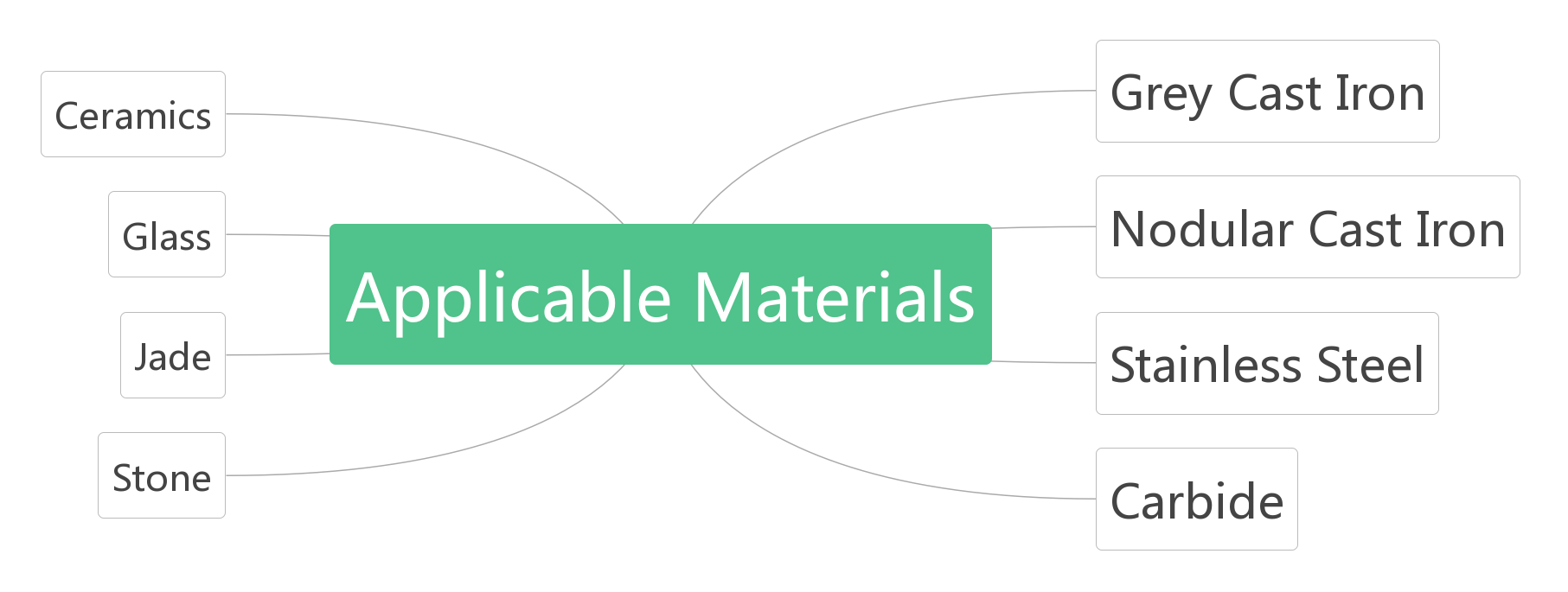

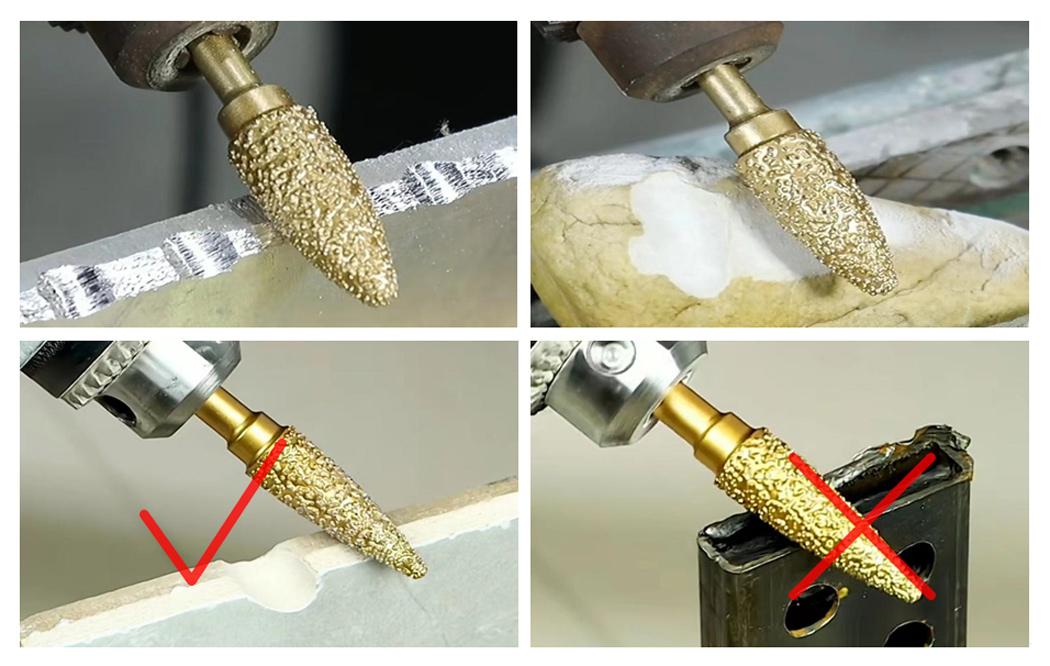

Product Name: Diamond Grinding Burr/Head Product Model: Cylindrical-A/Ball Nosed Cylinder-C/Ball Nosed Tree-F Head Material: Diamond Product Application: 1. The mold part is ground and polished. 2 Deburring and trimming of stainless steel. 3 Die hole repair processing. 4 Slotting and grinding of steel parts. Head Diameter: 6mm/8mm/10mm/13mm/15mm/18mm/20mm Head Length: 30mm Shank Length: 30mm Advantage: 1. Diamond material, not easy to deform. 2. Less dust, more environmental protection. 3. High manganese steel, thickened matrix. 4. The reinforcing rod is designed to prolong the service life. Product Introduce: This product adopts diamond coating, mainly used for casting iron, wood, cement, metal, stone, glass, China and other materials grinding finishing and polishing. It needs to be used with a grinder, can not be used alone.

Product Name: Diamond Grinding Burr/Head Product Model: Cylindrical-A/Ball Nosed Cylinder-C/Ball Nosed Tree-F Head Material: Diamond Product Application: 1. The mold part is ground and polished. 2 Deburring and trimming of stainless steel. 3 Die hole repair processing. 4 Slotting and grinding of steel parts. Head Diameter: 6mm/8mm/10mm/13mm/15mm/18mm/20mm Head Length: 30mm Shank Length: 30mm Advantage: 1. Diamond material, not easy to deform. 2. Less dust, more environmental protection. 3. High manganese steel, thickened matrix. 4. The reinforcing rod is designed to prolong the service life. Product Introduce: This product adopts diamond coating, mainly used for casting iron, wood, cement, metal, stone, glass, China and other materials grinding finishing and polishing. It needs to be used with a grinder, can not be used alone. 1. Processing and repair of molds. 2. Stone engraving, engraving, cutting lines, grinding, hollowing. 3. Glass carving. 4. Cleaning of casting, forging, welding edges, burrs, welds. 5. Tooth grinding processing. 6. Chamfering and groove processing of various mechanical parts, cleaning pipes, finishing the inner hole surface of mechanical parts. 7. Modification of workpiece geometry. 8. Dental clinic engraving.

1. Processing and repair of molds. 2. Stone engraving, engraving, cutting lines, grinding, hollowing. 3. Glass carving. 4. Cleaning of casting, forging, welding edges, burrs, welds. 5. Tooth grinding processing. 6. Chamfering and groove processing of various mechanical parts, cleaning pipes, finishing the inner hole surface of mechanical parts. 7. Modification of workpiece geometry. 8. Dental clinic engraving.

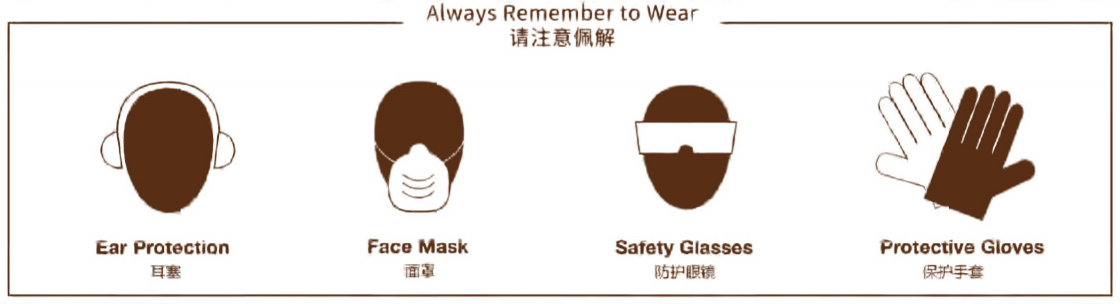

Brazing grinding head ● Long service life, more durable than ordinary grinding heads ● Less dust, more environmentally friendly ● Sharp grinding and high efficiency ● High manganese steel, thickened matrix1. The cast iron grinding head needs to be installed firmly and stably. 2. Idle for 1 minute before use to check whether the machine operates normally. 3. Wear protective equipment during operation. 4. When removing the cast iron grinding head, disconnect the power supply of the machine first.

Brazing grinding head ● Long service life, more durable than ordinary grinding heads ● Less dust, more environmentally friendly ● Sharp grinding and high efficiency ● High manganese steel, thickened matrix1. The cast iron grinding head needs to be installed firmly and stably. 2. Idle for 1 minute before use to check whether the machine operates normally. 3. Wear protective equipment during operation. 4. When removing the cast iron grinding head, disconnect the power supply of the machine first. 1. Work efficiency: the work efficiency is increased by 35%. For high hardness materials and sand inclusion castings, the work efficiency is increased by 5-10 time. 2. Benefit: for high hardness materials and sand inclusion castings, one piece is equal to 100-300 ordinary resin grinding pieces. 3. Environmental protection: the abrasive does not contain sulfur, does not fall off, and the dust and waste gas pollution are almost zero. 4. Safety: high strength steel matrix is adopted, and there is no potential safety hazard caused by debris flying out.Traditional grinding head ● Short service life, uneven stress will produce deformation ● The dust is large, causing harm to human body ● Short service life, manual replacement is time-consuming and laborious ● Ordinary material handle, easy to break, poor balance

1. Work efficiency: the work efficiency is increased by 35%. For high hardness materials and sand inclusion castings, the work efficiency is increased by 5-10 time. 2. Benefit: for high hardness materials and sand inclusion castings, one piece is equal to 100-300 ordinary resin grinding pieces. 3. Environmental protection: the abrasive does not contain sulfur, does not fall off, and the dust and waste gas pollution are almost zero. 4. Safety: high strength steel matrix is adopted, and there is no potential safety hazard caused by debris flying out.Traditional grinding head ● Short service life, uneven stress will produce deformation ● The dust is large, causing harm to human body ● Short service life, manual replacement is time-consuming and laborious ● Ordinary material handle, easy to break, poor balance