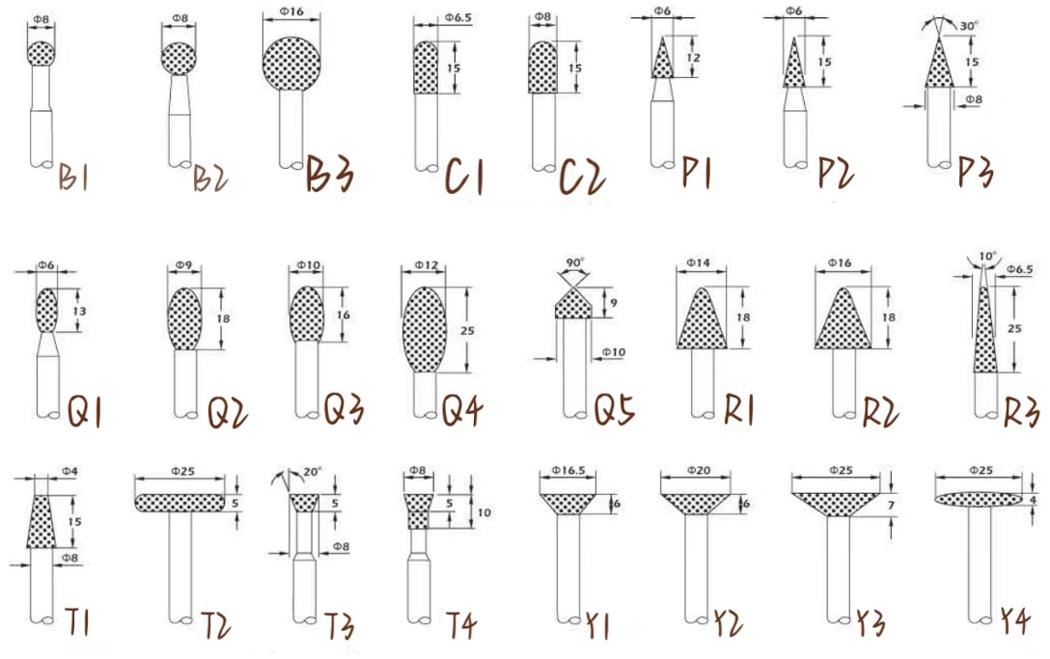

Item Name: Emery Grinding Needle Itemt Model: B/C/P/Q/R/T/Y Item Head Material: Diamond Item Quantity: 50 pcs/set Total Length: 45mm Shank Diameter: 3.2mm ItemUsage: Mainly used in stone, ceramics, glass, cemented carbide, gem, jade processing and other fields. Advantages: It is made of artificial diamond and high-strength diamond electroplating. The sand is uniform and durable. Product Introduce:This product adopts diamond coating, It is widely used in carving, grinding, trimming, fine grinding and inner hole grinding of ceramics, glass, gemstones, alloys and other wear-resistant materials.

Item Name: Emery Grinding Needle Itemt Model: B/C/P/Q/R/T/Y Item Head Material: Diamond Item Quantity: 50 pcs/set Total Length: 45mm Shank Diameter: 3.2mm ItemUsage: Mainly used in stone, ceramics, glass, cemented carbide, gem, jade processing and other fields. Advantages: It is made of artificial diamond and high-strength diamond electroplating. The sand is uniform and durable. Product Introduce:This product adopts diamond coating, It is widely used in carving, grinding, trimming, fine grinding and inner hole grinding of ceramics, glass, gemstones, alloys and other wear-resistant materials. It is widely used in carving, grinding, trimming, fine grinding and inner hole grinding of ceramics, glass, gemstones, alloys and other wear-resistant materials. It is used to polish and cut the surface of the object and grind the cutter.

It is widely used in carving, grinding, trimming, fine grinding and inner hole grinding of ceramics, glass, gemstones, alloys and other wear-resistant materials. It is used to polish and cut the surface of the object and grind the cutter. 1. High quality material, wear-resistant and durable, long service life. 2. Provide a variety of specifications, widely used. 3. Sharp products, high grinding efficiency. 4. No dust pollution. 5. Alloy forged handle, hard and durable.

1. High quality material, wear-resistant and durable, long service life. 2. Provide a variety of specifications, widely used. 3. Sharp products, high grinding efficiency. 4. No dust pollution. 5. Alloy forged handle, hard and durable.

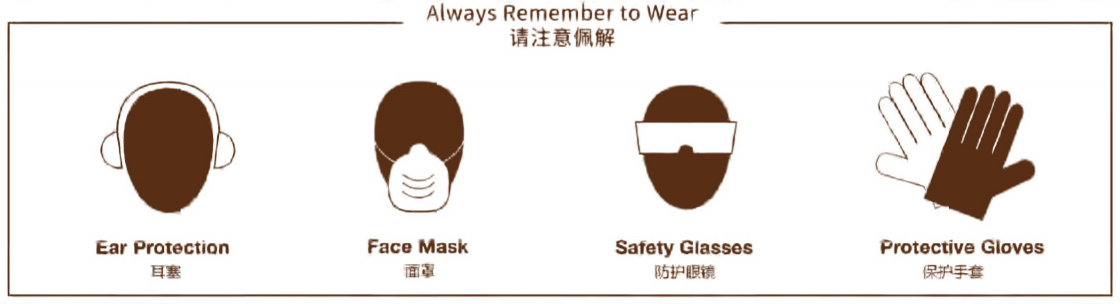

1. We are professional carbide burr manufacturer since 1992. With 30 years of abrasive tools, and the grinding time of workpieces is definitely longer than that of others. 2. Each product will be tested before leaving the factory to ensure that the quality of the product is ok. 3. We have a large stock of regular popular models and can arrange delivery within seven days.1. When the tool is newly installed, it must be tested whether the tool jumps. If it does, it cannot be operated directly. It can only be used after it is adjusted to not jump. Otherwise, the tools will wear out quickly and the carved objects will not be smooth. Adjustment method: gently tap the tool handle that rotates at high speed with a small wrench that changes the collet until the tool is stable. It is strictly forbidden to knock the electronic machine. The adjustment method is to loosen the collet and turn the tool to an angle or extend and retract a little. 2. Be sure to drain water for cooling (such as the dripping device in the hospital) so that it will be worn and scrapped soon. For dry drilling, the diamond on the tool head will be graphitized due to overheating. 3. During drilling, try to avoid shaking, because shaking will cause local damage to the tool and accelerate the damage of the whole tool. 4. Rotate as high as possible. Generally, the linear speed shall not be less than 10-20 meters per second. 5. Press gently. Diamond tools process workpieces by grinding. Excessive force makes grinding difficult to eliminate and tools are easy to be damaged. 6. Adding water to the diamond grinding rod can improve the wear resistance and sharpness of the grinding head, and then improve the service life.

1. We are professional carbide burr manufacturer since 1992. With 30 years of abrasive tools, and the grinding time of workpieces is definitely longer than that of others. 2. Each product will be tested before leaving the factory to ensure that the quality of the product is ok. 3. We have a large stock of regular popular models and can arrange delivery within seven days.1. When the tool is newly installed, it must be tested whether the tool jumps. If it does, it cannot be operated directly. It can only be used after it is adjusted to not jump. Otherwise, the tools will wear out quickly and the carved objects will not be smooth. Adjustment method: gently tap the tool handle that rotates at high speed with a small wrench that changes the collet until the tool is stable. It is strictly forbidden to knock the electronic machine. The adjustment method is to loosen the collet and turn the tool to an angle or extend and retract a little. 2. Be sure to drain water for cooling (such as the dripping device in the hospital) so that it will be worn and scrapped soon. For dry drilling, the diamond on the tool head will be graphitized due to overheating. 3. During drilling, try to avoid shaking, because shaking will cause local damage to the tool and accelerate the damage of the whole tool. 4. Rotate as high as possible. Generally, the linear speed shall not be less than 10-20 meters per second. 5. Press gently. Diamond tools process workpieces by grinding. Excessive force makes grinding difficult to eliminate and tools are easy to be damaged. 6. Adding water to the diamond grinding rod can improve the wear resistance and sharpness of the grinding head, and then improve the service life.