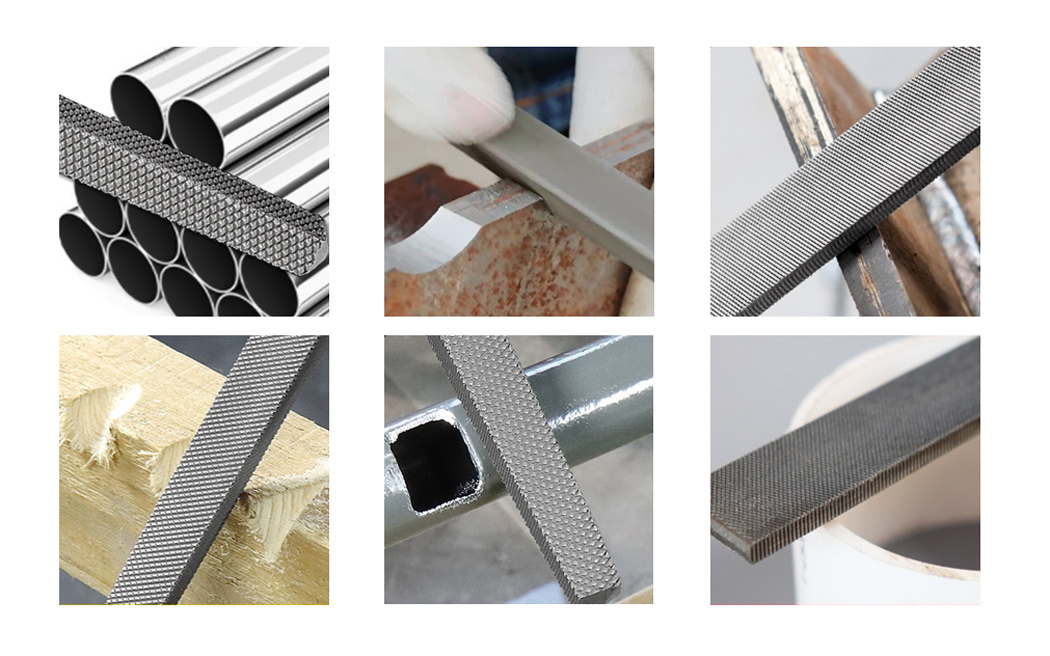

The product is made of pure carbon tool steel with high hardness and clear tooth lines. It is a manual tool mainly used for grinding and dressing metal materials. Can be used alone.

The product is made of pure carbon tool steel with high hardness and clear tooth lines. It is a manual tool mainly used for grinding and dressing metal materials. Can be used alone.| No | Specification Mm/Inch | Width/mm | Thickness/mm | Weight/g |

| GT10104 | 100mm/4” | 12 | 3 | 32 |

| GT10105 | 125mm/5” | 14 | 3.2 | 40 |

| GT10106 | 150mm/6” | 16 | 3.5 | 70 |

| GT10108 | 200mm/8” | 20 | 4.2 | 140 |

| GT10110 | 250mm/10” | 24 | 5.2 | 250 |

| GT10112 | 300mm/12” | 28 | 6.2 | 417 |

| GT10114 | 350mm/14” | 32 | 7.2 | 627 |

| GT10116 | 400mm/16” | 36 | 8 | 900 |

| GT10118 | 450mm/18” | 40 | 9 | 1200 |

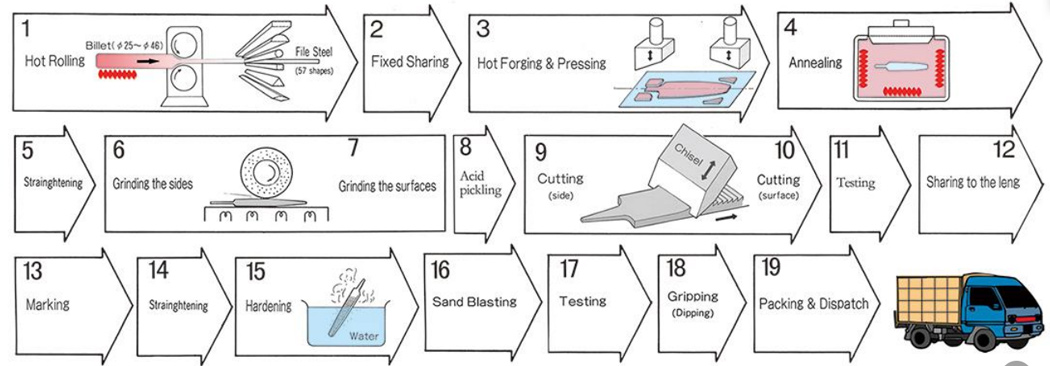

1. We are professional steel files manufacturer since 1992. With 30 years of abrasive tools, and the grinding time of work pieces is definitely longer than that of others. 2. Our material is 100% real Carbon Steel T12. Some factory used lower cost material to make cheaper quality. 3. High temperature quenching to improve the resistance and hardness of products. 4. The tooth tip is sharp, which provides guarantee for fast grinding, and the tooth tip is more wear-resistant after quenching process. 5. Handle connection adopts exclusive connection technology to prevent the handle from falling off during use.● Small Orders Accepted ● Customized Brand-name ● Prompt Delivery● Experienced Staff ● Good Product Performance ● Green Product

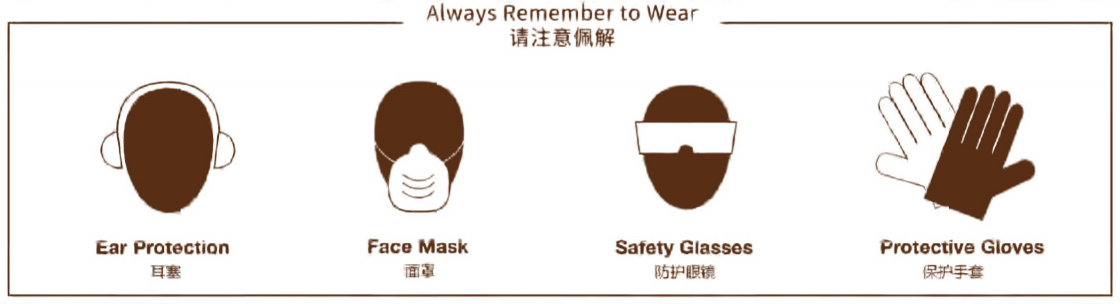

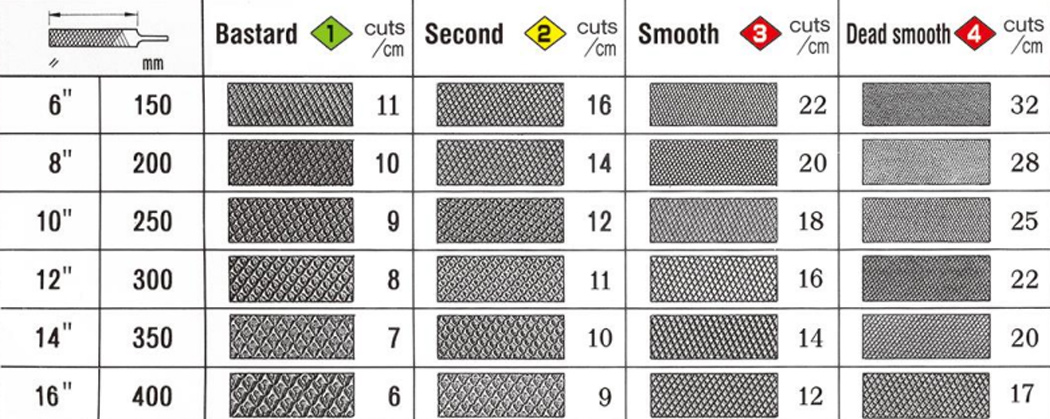

1. We are professional steel files manufacturer since 1992. With 30 years of abrasive tools, and the grinding time of work pieces is definitely longer than that of others. 2. Our material is 100% real Carbon Steel T12. Some factory used lower cost material to make cheaper quality. 3. High temperature quenching to improve the resistance and hardness of products. 4. The tooth tip is sharp, which provides guarantee for fast grinding, and the tooth tip is more wear-resistant after quenching process. 5. Handle connection adopts exclusive connection technology to prevent the handle from falling off during use.● Small Orders Accepted ● Customized Brand-name ● Prompt Delivery● Experienced Staff ● Good Product Performance ● Green Product ● Net Weight: 24kg ● Gross Weight: 25kg ● Export Carton Dimensions L/W/H: 37cm×19cm×15cm● FOB Port: Any port ● Lead Time: 7-30 Days● In order to avoid inappropriate products and processes in the work, it is recommended to purchase three types of files: bastard, second and smooth, which can increase work efficiency. ● Do not use a new file on hard metal. Do not use files on the hardening steel. ● If the aluminium pieces or the other casting are rough or sanded, after rubbed off, then we can use the file. ● Using tools can be dangerous, always take care and keep away from Children. ● Wear protective eyewear in work area at all time. ● Select correct type and size of tool for work ● Use one side of the file firstly. after it becomes blunt, then turn to the other side of the file.

● Net Weight: 24kg ● Gross Weight: 25kg ● Export Carton Dimensions L/W/H: 37cm×19cm×15cm● FOB Port: Any port ● Lead Time: 7-30 Days● In order to avoid inappropriate products and processes in the work, it is recommended to purchase three types of files: bastard, second and smooth, which can increase work efficiency. ● Do not use a new file on hard metal. Do not use files on the hardening steel. ● If the aluminium pieces or the other casting are rough or sanded, after rubbed off, then we can use the file. ● Using tools can be dangerous, always take care and keep away from Children. ● Wear protective eyewear in work area at all time. ● Select correct type and size of tool for work ● Use one side of the file firstly. after it becomes blunt, then turn to the other side of the file.

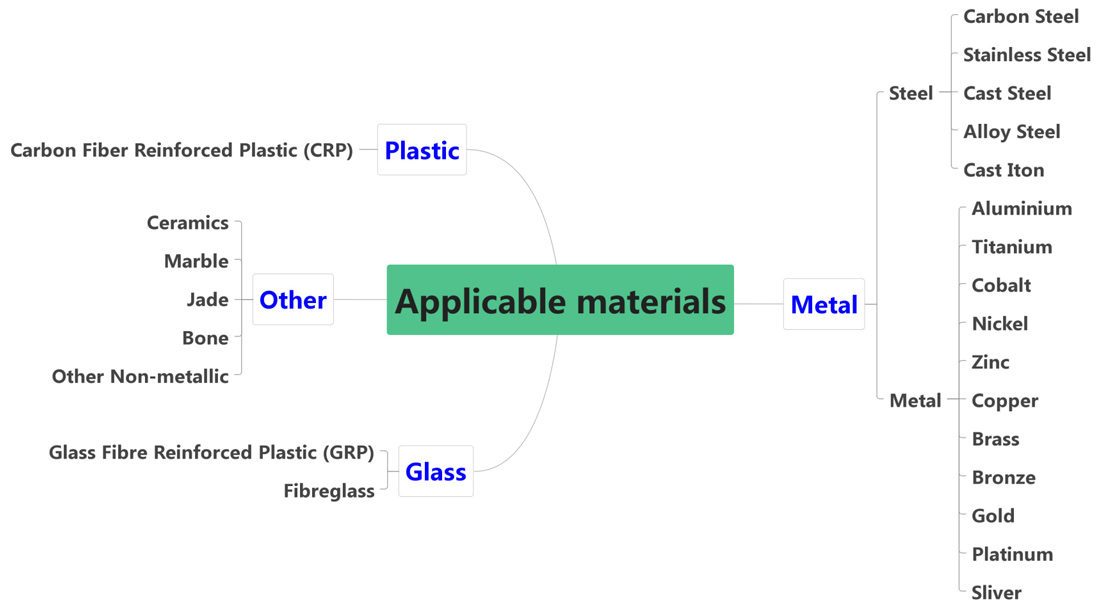

Bastard Cuts: suitable for rough workpiece and preliminary shaping Second Cuts: suitable for machining with a machining allowance greater than 0.5mm. Large cutting volume machining can be carried out to remove the part with more work piece allowance. Smooth Cuts: suitable for machining with a machining allowance of 0.5-0.1mm. They can be polished carefully to approach the required size of the work piece. Dead Smooth Cuts: Dead Smooth Cuts file is the file with the smallest teeth. Its cutting effect is very small. It is mainly used to trim the roughness of the work piece surface. Used for finishing of work piece surface.Using tools can be dangerous, always take care and keep away from Children. Wear protective eyewear in work area at all time. Select correct type and size of tool for work.1.What is a hand file used for? Used for fine finishing of metal, wood, leather and other surfaces. According to the different profile, it can be divided into flat file, round file, square file, triangle file, diamond file, half round file, knife file and so on. 2.What is the name of hand file? A flat file with a rectangular shape. Also known as a board file. 3.How do I select a right file? (1). Selection of file section shape. The section shape of the file shall be selected according to the shape of the part to be filed, so that the two shapes are compatible. When filing the inner circular arc surface, choose semi-circular file or round file (work piece with small diameter); When filing the inner corner surface, choose triangular file; When filing the inner right angle surface, flat file or square file can be selected. When using flat file to file the inner right angle surface, pay attention to make the narrow surface (smooth edge) of the file without teeth close to one surface of the inner right angle to avoid damaging the right angle surface. (2). Selection of file tooth thickness. The thickness of the file teeth should be selected according to the allowance of the work piece, machining accuracy and material properties. Coarse tooth file is suitable for machining work pieces with large allowance, low dimensional accuracy, large form and position tolerance, large surface roughness value and soft material; Instead, choose a fine tooth file. When in use, it should be selected according to the machining allowance, dimensional accuracy and surface roughness required by the workpiece. (3). Selection of file size and specification. The size and specification of the file shall be selected according to the size of the workpiece to be processed and the machining allowance. When the machining size is large and the allowance is large, the file with large size specification shall be selected, on the contrary, the file with small size specification shall be selected. (4). Selection of tooth pattern of file. The tooth pattern of the file should be selected according to the properties of the material of the workpiece being filed. When filing aluminum, copper, mild steel and other soft material work pieces, it is best to choose a single tooth pattern (milling tooth) file. The single tooth file has large rake angle, small wedge angle and large chip holding groove. The chip is not easy to be blocked and the cutting edge is sharp.

Bastard Cuts: suitable for rough workpiece and preliminary shaping Second Cuts: suitable for machining with a machining allowance greater than 0.5mm. Large cutting volume machining can be carried out to remove the part with more work piece allowance. Smooth Cuts: suitable for machining with a machining allowance of 0.5-0.1mm. They can be polished carefully to approach the required size of the work piece. Dead Smooth Cuts: Dead Smooth Cuts file is the file with the smallest teeth. Its cutting effect is very small. It is mainly used to trim the roughness of the work piece surface. Used for finishing of work piece surface.Using tools can be dangerous, always take care and keep away from Children. Wear protective eyewear in work area at all time. Select correct type and size of tool for work.1.What is a hand file used for? Used for fine finishing of metal, wood, leather and other surfaces. According to the different profile, it can be divided into flat file, round file, square file, triangle file, diamond file, half round file, knife file and so on. 2.What is the name of hand file? A flat file with a rectangular shape. Also known as a board file. 3.How do I select a right file? (1). Selection of file section shape. The section shape of the file shall be selected according to the shape of the part to be filed, so that the two shapes are compatible. When filing the inner circular arc surface, choose semi-circular file or round file (work piece with small diameter); When filing the inner corner surface, choose triangular file; When filing the inner right angle surface, flat file or square file can be selected. When using flat file to file the inner right angle surface, pay attention to make the narrow surface (smooth edge) of the file without teeth close to one surface of the inner right angle to avoid damaging the right angle surface. (2). Selection of file tooth thickness. The thickness of the file teeth should be selected according to the allowance of the work piece, machining accuracy and material properties. Coarse tooth file is suitable for machining work pieces with large allowance, low dimensional accuracy, large form and position tolerance, large surface roughness value and soft material; Instead, choose a fine tooth file. When in use, it should be selected according to the machining allowance, dimensional accuracy and surface roughness required by the workpiece. (3). Selection of file size and specification. The size and specification of the file shall be selected according to the size of the workpiece to be processed and the machining allowance. When the machining size is large and the allowance is large, the file with large size specification shall be selected, on the contrary, the file with small size specification shall be selected. (4). Selection of tooth pattern of file. The tooth pattern of the file should be selected according to the properties of the material of the workpiece being filed. When filing aluminum, copper, mild steel and other soft material work pieces, it is best to choose a single tooth pattern (milling tooth) file. The single tooth file has large rake angle, small wedge angle and large chip holding groove. The chip is not easy to be blocked and the cutting edge is sharp.